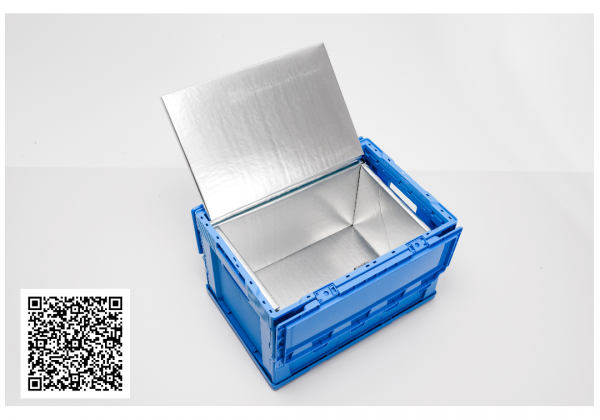

Plastic logistics box

- Product Features

- You can choose a stack of logistics boxes.

- The storage is neat, the stacking is easy, and the economy saves time and effort.

- The plastic material is low in pollution and easy to recycle.

product description

The logistics box is mainly a container that is loaded with many items and is convenient for logistics transportation. According to different needs, the logistics box is divided into bottom net, whole net, bottom dense, full secret and other styles. The logistics box (drinks) is a classification developed for beverage distribution, such as a goat milk box for transporting goat milk bottles and a beer box for glass bottled beer.

application

In compliance with environmental regulations, the plastics used can be recycled and reused 100%, saving processing costs.

No iron spikes, good safety, no puncturing bags or personal injury.

It is smoke-free and pest-free, and meets the requirements of packaging and environmental protection regulations of exported countries.

Easy to clean, no bacteria, mold. It can prevent termites and has good hygiene.

Patented anti-slip design that stacks on top of one another, saving space and shipping costs.

.jpg)

Material

We insist on using high quality virgin material.PP (polypropylene)

Polypropylene (PP) is a thermoplastic resin with high density and semi-crystalline polymer. It has superior comprehensive performance, mainly reflected in solvent resistance, high temperature resistance, acid and alkali resistance and bending and heavy pressure.

Material characteristics

Among the commonly used plastic materials, the density of the PP product is only 0.91 g/cm3, which means that the PP material has the lightest weight in the same volume of the product.

PP has good chemical stability, and its molecules are stable and difficult to dissolve and deform in most acid-base solvents or extreme environments.

Due to the high crystallinity of PP material and the very regular molecular structure, it has excellent mechanical properties, tensile properties and good stress crack resistance, and has a high bending fatigue life.

Excellent heat resistance, PP material processing temperature is about 180-240 degrees Celsius, the chemical composition at high temperatures is still very stable. Under normal use and no external force, it can be used for a long time in an environment of 100 degrees Celsius without deformation.

Material characteristics

Among the commonly used plastic materials, the density of the PP product is only 0.91 g/cm3, which means that the PP material has the lightest weight in the same volume of the product.

PP has good chemical stability, and its molecules are stable and difficult to dissolve and deform in most acid-base solvents or extreme environments.

Due to the high crystallinity of PP material and the very regular molecular structure, it has excellent mechanical properties, tensile properties and good stress crack resistance, and has a high bending fatigue life.

Excellent heat resistance, PP material processing temperature is about 180-240 degrees Celsius, the chemical composition at high temperatures is still very stable. Under normal use and no external force, it can be used for a long time in an environment of 100 degrees Celsius without deformation.

HDPE (high density polyethylene)

Plastic Products

High-density polyethylene (HDPE) is made of ethylene. Due to its high crystallinity, high density, strong tensile strength, permeability resistance, and good chemical stability, it is widely used in the production of refrigerator containers. Storage containers, sealing covers, cling film and other products.

Material characteristics

The friction coefficient is low.

Excellent electrical insulation.

Light weight, easy to process, and in direct contact with food.

Excellent toughness and elastic strength are maintained even in low temperature environments.

Excellent chemical stability. At room temperature, it is insoluble in any organic solvent, resistant to acid, alkali and various mites.

High-density polyethylene (HDPE) is made of ethylene. Due to its high crystallinity, high density, strong tensile strength, permeability resistance, and good chemical stability, it is widely used in the production of refrigerator containers. Storage containers, sealing covers, cling film and other products.

Material characteristics

The friction coefficient is low.

Excellent electrical insulation.

Light weight, easy to process, and in direct contact with food.

Excellent toughness and elastic strength are maintained even in low temperature environments.

Excellent chemical stability. At room temperature, it is insoluble in any organic solvent, resistant to acid, alkali and various mites.