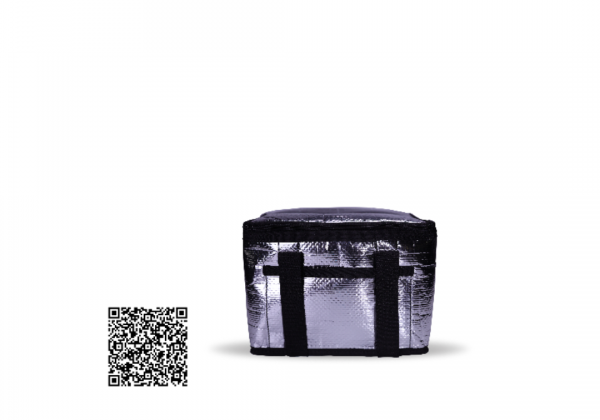

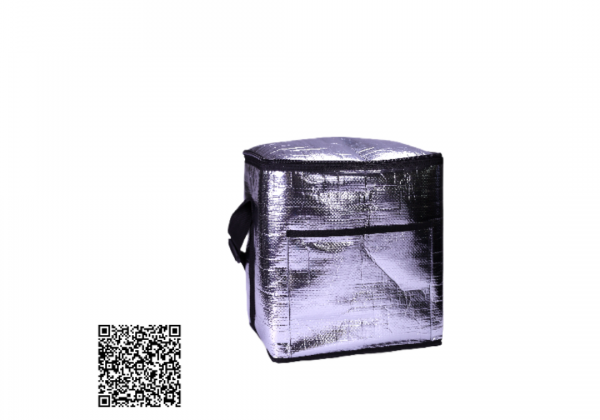

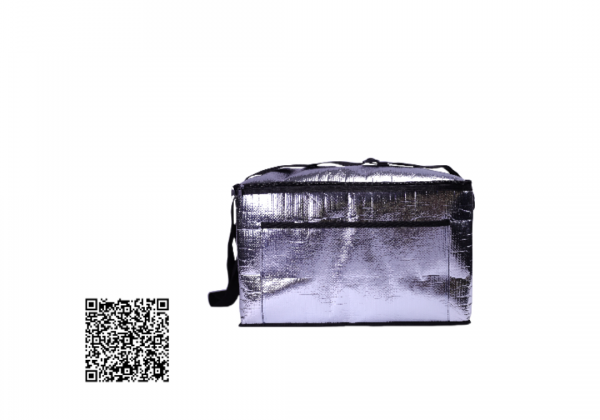

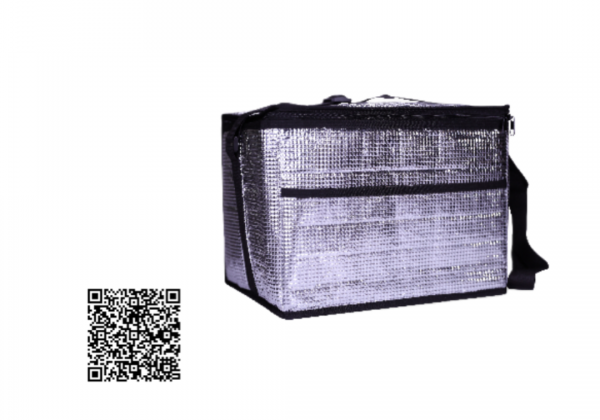

Cold insulation box, cold storage bag, cold insulation cover

- Product Features

- Buying a lease, repairing is simple

- Simple maintenance, long-lasting and durable

- Energy saving and carbon reduction, reducing costs

- Green design, environmental awareness

- Compact design, free space

- Customer requirements, mission must

product description

1.The Japanese-style production system with total quality management that ensures the highest ruality. 2.Detachable design might save 50% storage space when disassembled. Modular design makes it maintaining easily,an extends the service life by changing damaged thermal insulation wall. 3.The maximum bearable weight is up to 400 KG.

application

✱Design concept: VIP insulation material lasts for a long time, reducing the demand of refrigerant and dry ice; sandwich layer structure of insulation layer, enhancing the ability of planting; the box can be folded for easy storage and transportation.

✱ Suitable for storage and storage of low temperature products for a long time

✱The specific thermal conductivity of the cryogenic tank: ℷג≤8.0mw/m.k

.png)

.png)

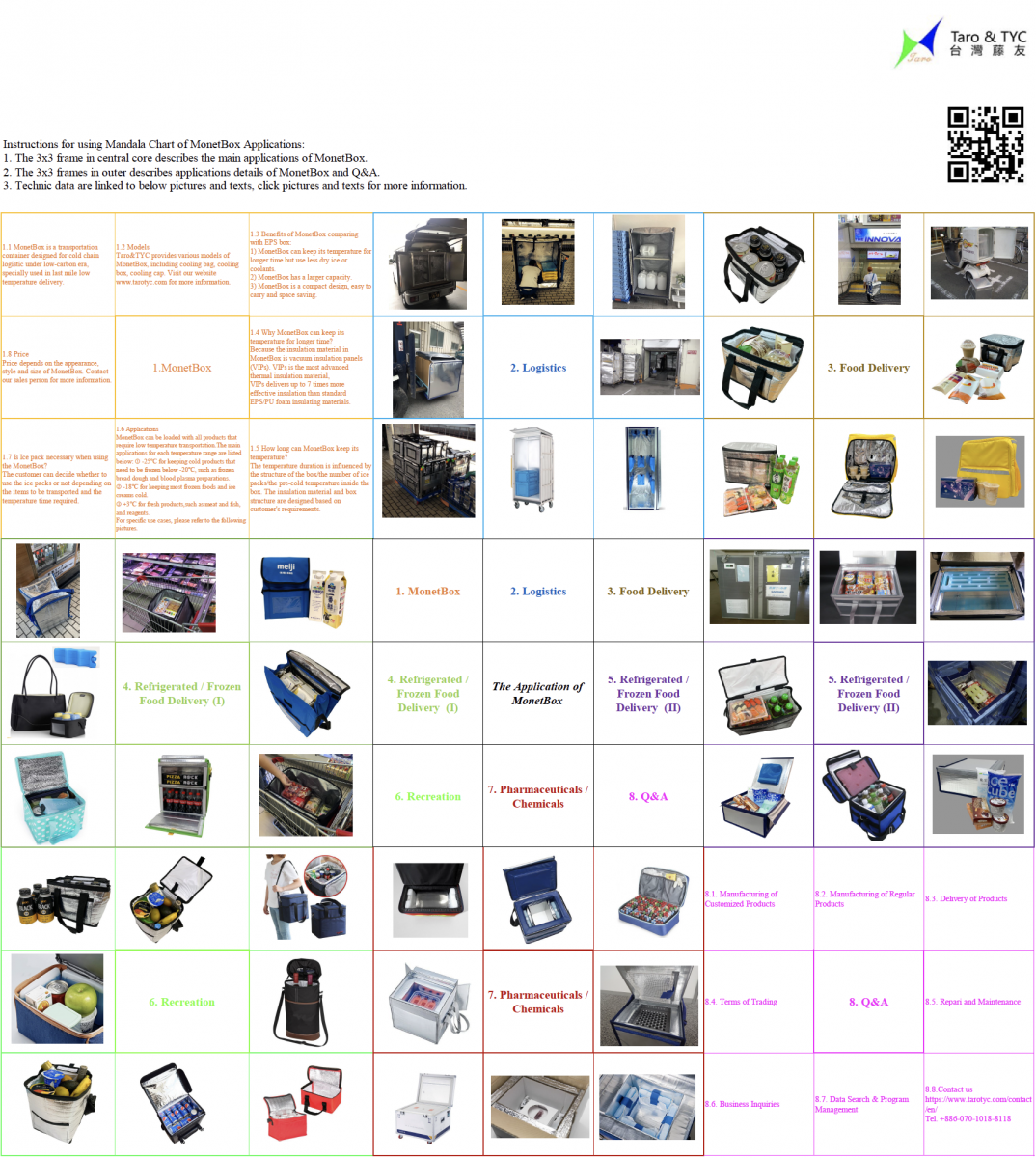

Monet Box,Monet Bag application

Material

We insist on using high quality virgin material.Foamed PU

Polyurethane (commonly abbreviated as PU) refers to a class of polymers containing a characteristic unit of carbamate in the main chain.

This polymer material is widely used in industrial fields such as adhesives, coatings, low-speed tires, gaskets, and car mats. In the daily life area, polyurethane is used to make various foams and plastic sponges. Due to the very low thermal conductivity of polyurethane, its materials have begun to mature in Western countries such as Europe and the United States.

This polymer material is widely used in industrial fields such as adhesives, coatings, low-speed tires, gaskets, and car mats. In the daily life area, polyurethane is used to make various foams and plastic sponges. Due to the very low thermal conductivity of polyurethane, its materials have begun to mature in Western countries such as Europe and the United States.

Thermal insulation film

It can isolate more than 90% of heat energy, and the indoor and outdoor temperature difference is up to 5 degrees. It can easily achieve energy saving and energy saving. The use of large, wide-shield glass can accomplish the mission of UV resistance and efficient insulation without sacrificing invincible beauty.

Getter

An auxiliary object that directly absorbs the residual gas inside the device by utilizing the physical and chemical properties of the raw material, and the getter is capable of forming a stable combination (physical or chemical combination) with the remaining gas to achieve the removal of the airtightness. The purpose of the residual gas inside the original is to protect the vacuum efficiency of the sealed component during operation, so the getter is equivalent to a physico-chemical vacuum pump assembled inside the sealed device.

Vacuum insulation PANELS(VIPs)

Vacuum insulation board (VIP board) is the abbreviation of English Vacuum Insulation Panel. It is one kind of vacuum insulation material. It is made up of composite core and vacuum protection surface. It effectively avoids heat transfer caused by air convection. The thermal conductivity can be greatly reduced, less than 0.035w/(m2.k), and does not contain any ODS (ozone depleting substances) materials. It is environmentally friendly and energy efficient. It is the most advanced and efficient insulation material in the world.